M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Technology > [Soldering issues] Wettability issues (Solder pastes)

Poor wettability makes less bonding area and bonding reliability.

The causes of wetting issues include reflow profile problems and deterioration of components and boards.

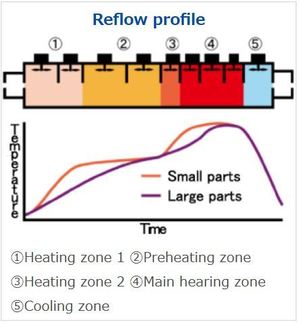

“Trapezoidal profile” is long preheating and main heating. The melting point of the solder is about 220 °C, while the heat resistant temperature of the parts is around 250 °C. Long preheating zone eliminate the temperature difference due to the size of parts, it prevents wettabiliy issues due to heat shortage of large parts and failure due to overheating of small parts.

Generally the preheating temperature is 150 to 180 ° C and the time is 90 to 120 seconds. During preheating, the flux of solder paste starts the reaction by heat, gradually loses its activity and the wettability decreases. So it is ideal to preheat at as low a temperature as possible and in as short a time as possible within the range where the temperature of the part rises to around 240 ° C during main heating.

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.