M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Good wettability type 1001 series

Higher heat resistance can reduce defect of non-wetting and non-melting

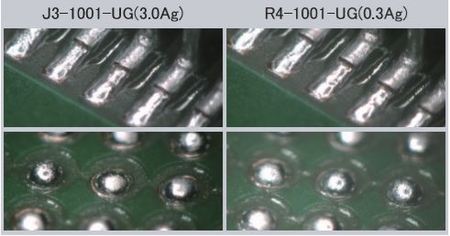

●High temperature preheating test

Good wettability in severe conditions

Condition:Atmospheric

Pre heat:200℃ 120 seconds

Component:0.4mm pitch QFP φ0.30mm dot

Prevent quality deterioration during transportation.

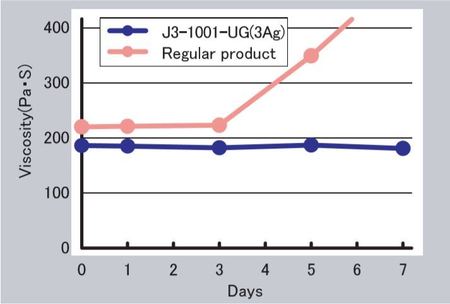

●35℃ deterioration test

Prevent quality deterioration during transportation

With new technology of controlling activator at room temperature, stable at long time printing and transportation.

●Confirmation of the shape of the printed solder paste

Stable shape after long time printing

J3-1001-UG(3Ag)

0.4mm pitch QFP

Stencil thickness:0.12mm

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) R4 (Sn:Bal / Ag 0.3 / Cu 0.7) |

|---|---|

| Flux type | MIL-RMA |

| Halide contents | Less than 0.02% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 12.0% |

| Deterioration(Pa・S) | 190 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Flux name | 1001 |

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) R4 (Sn:Bal / Ag 0.3 / Cu 0.7) |

|---|---|

| Flux type | MIL-RMA |

| Halide contents | Less than 0.02% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 12.0% |

| Deterioration(Pa・S) | 190 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Flux name | 1001 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.