M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] High reliability type for automotive 1500 series

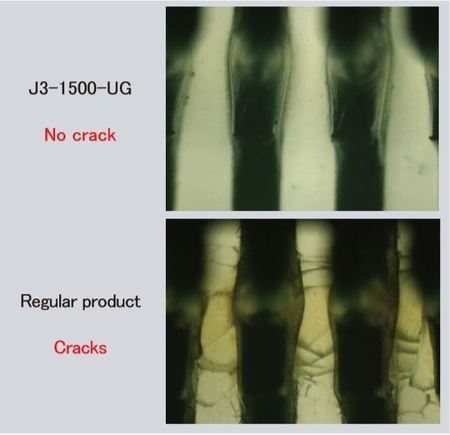

Elasticity of flux residue of applying special resin prevents crack of residue after soldering and helps to improve surface insulation resistance greatly

●Thermal shock test(QFP shoot in transmitted light)

【Conditions】

-40℃ to 80℃ 30min 168 Cycles,

0.5mm pitch QFP

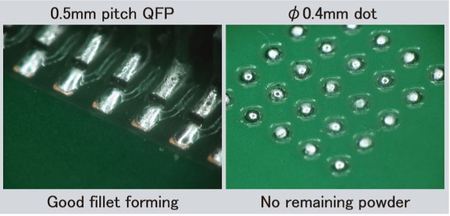

Select suitable activators for synthetic resin and the wettability is almost same as conventional solder paste

●Test by reflow soldering

Atmospheric:N2

Pre heat:150~200℃ 120 seconds

Main heat:240~245℃, 45 seconds

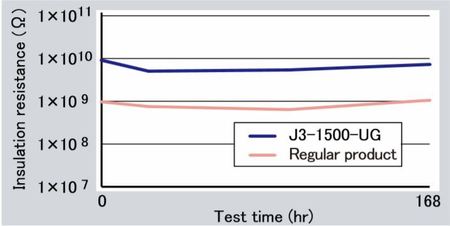

Select suitable base resin and activators in order to get high surface insulation resistance.

●Surface insulation resistance test

Achieve a high insulation resistance value than regular products

【Conditions】

Test board:JIS-II

Voltage:100V

Temp:85C

Humidity:85%

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) |

|---|---|

| Flux type | JIS-AA |

| Halide contents | Less than 0.02% |

| Powder particle size(μm) | 38~20(Type 4) |

| Flux contents(%) | 12.0% |

| Deterioration(Pa・S) | 210 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 1.0×109Ω |

| Electrochemical migration | No migration |

| Flux name | 1500 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.