M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Flux cored solder wire] For Aluminum wire soldering K4-C601-3

Solderable by iron to aluminum wire, used such as in the HDD of the actuator.

●Soldering test to aluminum

Solderable to aluminum

Put solder wire on aluminum board and heat by 270℃

Additive elements achieve high soldering reliability and prevent the galvanic corrosion that occurs between the aluminum material and solder.

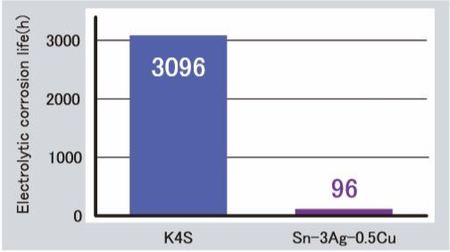

●Electrolytic corrosion test

Measure the time until the solder delamination occurs, stored in 40℃ of artificial seawater, after soldering the two aluminum plates

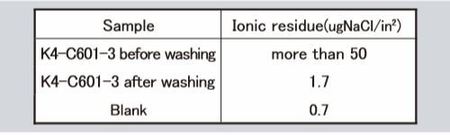

Apply water-soluble base material instead of rosin.The residue after soldering is possible to wash away easily with water.

●Ionic residue test

The flux residue is possible to clean with water

【Test method】JIS Z 3197 8.5.2

【Condition】

Cleaning solution:Pure water

Washing temp:50℃

Washing time:1min

Number of washings:3 times

| Alloy type | K4 (Sn:Bal / Ag 3.5 / Ni 0.2) |

|---|---|

| Flux type | Fluorine type |

| Flux contents (%) | 3.0% |

| Halide contents | 17%~23% |

| Copper plate corrosion test | No corrosion (after cleaning with water) |

| Insulation resistance(Ω) | More than 1.0×108Ω (after cleaning with water) |

| Electrochemical migration | No migration (after cleaning with water) |

| Fluorine contents(%) | 20% |

| Flux name | C601 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.