M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Low residue type 6001 series

Reduce failure ratio of ICT test.Select special base material to reduce flux residue after soldering.

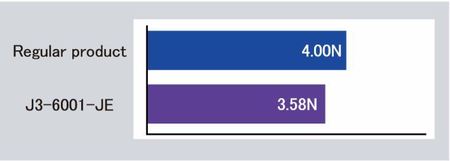

●Residue penetrate force test

Penetrating force is lower than regular product

Reflow with N2(O2 ratio 1000ppm) and measure penetrating force of checker pin with 10mm/sec speed until get contact

Apply special activator and achieved to get good wettability although the flux residue is lesser than regular solder paste

●Continuous wettability test

【Conditions】

Reflow with N2

O2 ratio 1000ppm

0.5mm pitch QFP

Stencil thickness 0.15mm

Prevent reaction between flux and solder powder and stabilize printing quality during long time continuous printing of paste.

●Shape of printed solder paste

Stable shape after long time printing

0.3mm QFP

Stencil thickness:0.12mm

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) |

|---|---|

| Flux type | MIL-RMA |

| Halide contents | 0.01%~0.05% |

| Powder particle size(μm) | 45~25(Type 3) |

| Flux contents(%) | 10.5% |

| Deterioration(Pa・S) | 195 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Flux name | 6001 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.