M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Solder paste (bottle)] Halogen free wash type 8825 series

Use a material that is highly miscible with solvents for the flux base.Improves the washability of the residue.

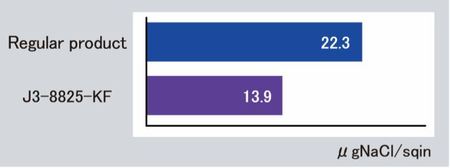

●Ionic residue test

After 1 min washing with IPA at 40℃, measure the amount oof ions.

Good washability in the ionic residue test

No intentional addition of chlorine(Cl) and bromine(Br), which generate dioxins.Compliant with most of halogen-free standards.

●Compliant situation of 8825 series

| Standards | Compliant situation |

|---|---|

| JPCA-ES01 | Compliant |

| IEC61249-2-21 | Compliant |

| IPC4101B | Compliant |

| JEITA ET-7304A | Non Compliant |

Comply to all of halogen free standards

Prevents the reaction of the flux and powder,in order to prevent the viscosity increasement during continuous printing.Enable to implement stability.

●Confirmation of the shape of the printed solder paste

Stable shape after long time printing

0.5mm QFP

Stencil thickness:0.15mm

| Alloy type | J3 (Sn:bal / Ag 3.0 / Cu 0.5) |

|---|---|

| Flux type | Halogen free |

| Halide contents | Less than 0.01% |

| Powder particle size(μm) | 38~25(Equivalent to type 4) |

| Flux contents(%) | 11.0% |

| Deterioration(Pa・S) | 190 |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Halogen contents(ppm) | Cl : Less than 900 Br : Less than 900 |

| Flux name | 8825 |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.