M anagement System

anagement System

ISO 9001:2015

ISO 14001:2015

Marshallstraat 18c, 5705 CN Helmond

Tel:+31-655701610

soldersolutions@ishikawa-europe.com

Home > Lead-free (EVASOL) > [Flux cored solder wire] Less spattering type MYK series

Select suitable flux base material for higher melting point alloy.Very few flux spattering can achieve high performance soldering.

●Flux spattering test by using soldering iron robot

Solderable to aluminum

Put solder wire on aluminum board and heat by 270℃

Selected materials suitable for rapid light heating achieves high workability. Good wettability with low Ag alloy can help to reduce cost.

●Confirmation of wettability with LASER soldering

【Condition】

Beam power:40W Wire diameter:φ0.8mm

Preheat:0.05 Wire feed:7mm/s,1.6s

Postheating:0.3s PCB:Cu,one side

Connector terminal:Brass,Sn plating on Ni

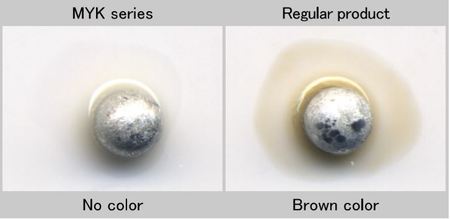

Good for after soldering appearance with transparent flux such as LED illumination.Can achiece higher productivity for outlook inspection.

●Put solder on white ceramic plate and heat with 270℃

Can achieve higher productivity for outlook inspection

| Alloy type | J3 (Sn:Bal / Ag 3.0 / Cu 0.5) R4 (Sn:Bal / Ag 0.3 / Cu 0.7) R8 (Sn:Bal / Cu 0.7) |

|---|---|

| Flux type | JIS-A MIL-RMA |

| Flux contents (%) | 3.0%、4.0%、6.0% |

| Halide contents | 0.08%~0.14% |

| Copper plate corrosion test | No corrosion |

| Copper mirror corrosion | No corrosion |

| Insulation resistance(Ω) | More than 5.0×108Ω |

| Electrochemical migration | No migration |

| Flux name | MYK |

Copyright © Ishikawa Metal Co.,LTD. All Rights Reserved.